Robot Transfer Units (RTUs) can significantly extend the usability of 6 Axis Robots by adding a 7th Axis, linear movement of the entire robot arm, to the robot which dramatically increases the operating envelope of the standard 6 or less axis robot.

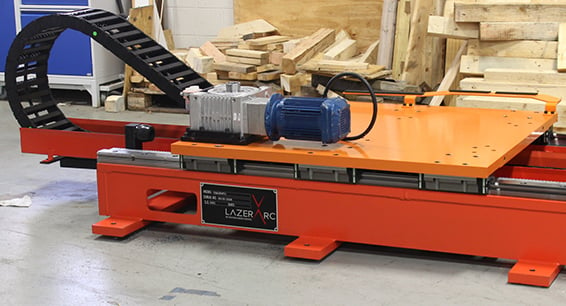

Automation engineers have creatively utilized RTUs to improve capacity and productivity and reduce labor costs, errors and safety incidents across a wide range of applications. When most people think of robots in factory automation, they imagine welding and painting operations on assembly lines or if they’re more knowledgeable perhaps they think of shuttling parts and tooling into and out of machining centers. RTU Robot Transfer Unit

RTU Robot Transfer Unit

However, significantly increasing the operating envelope of a robot arm can create an endless array of opportunities to automate a wide range of factory operations. The options are really only limited by the imagination.

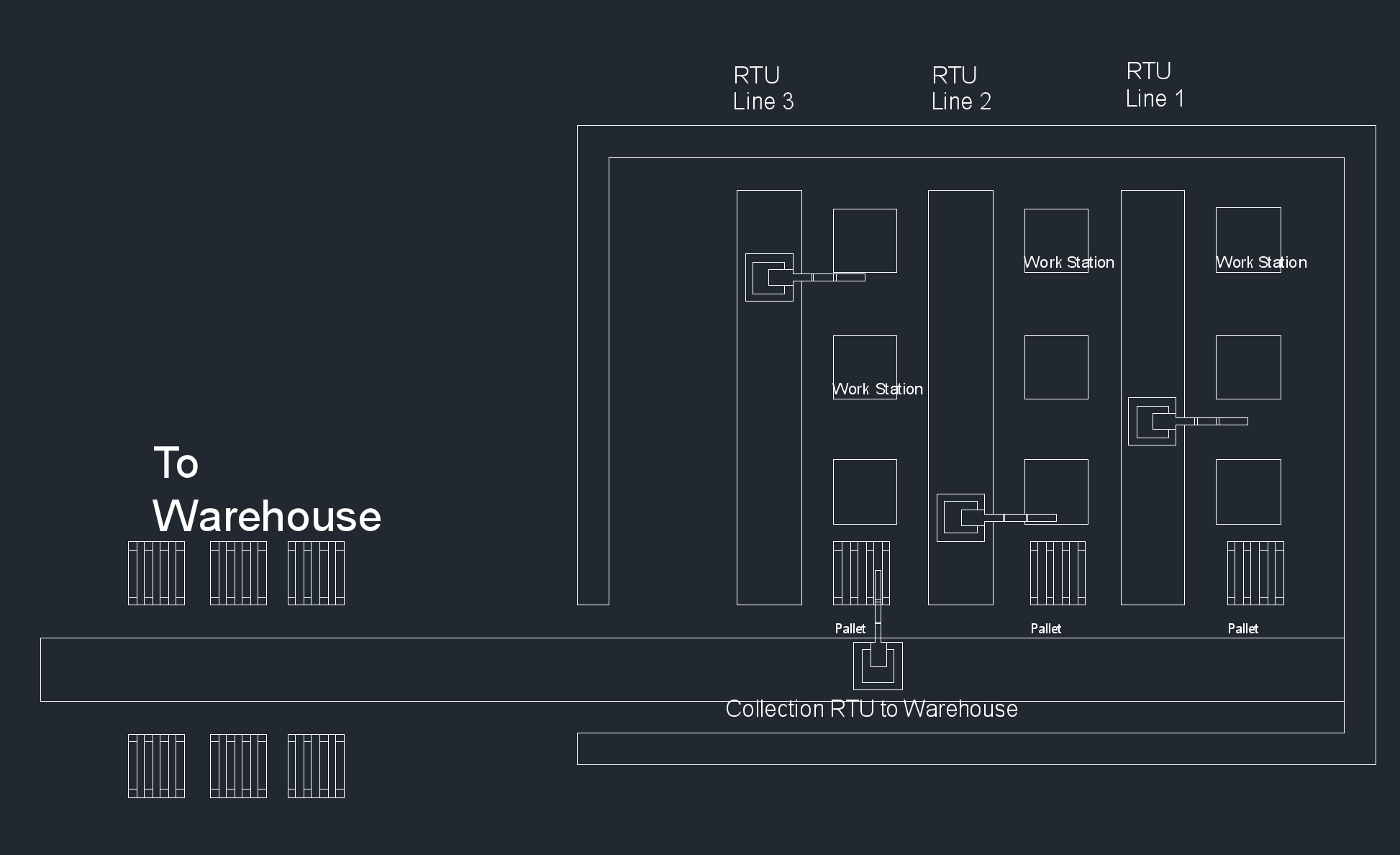

One under-represented application area for RTUs is in material handling. Material Handling Automation using MHUs (material handling units) can seem like an afterthought. However, as you think about it, an operator and forklift can be an expensive combination to operate. It can be tied up serving other areas or doing things like offloading trucks. It can be prone to errors and mis-haps. Perhaps an operator is out sick. A fully automated production operation needs to be running at capacity and often 24/7 - 365. Automating the provision of parts can ensure maximum uptime while reducing other costs. You can easily imagine a row of machining centers that are fed by an RTU. Now imagine a row of these RTU fed systems that are in turn fed by an RTU that extends into a material staging area or warehouse.

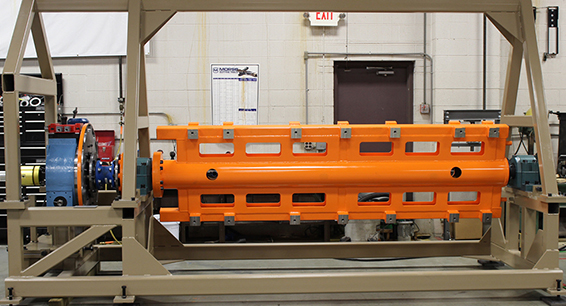

Robot Transfer Units (RTUs) give an additional axis that was otherwise foregone. The ability to transverse a room to complete multiple tasks. While the manufacturing process of most companies include Robots there is often a human worker component still in place to move one product from robot to robot, or line to line. When the production line in question is operating large, bulky, and heavy components that human job is daunting. Motion Index Drives has a solution, the addition of the 7th axis, the ability to translate the robot. Carriage Robot Transfer Units are incredibly useful, versatile, and most important, accurate. They allow for one robot to operate between different factory areas to complete a greater volume of tasks. Used in tandem with other robots on similar carriage RTUs a line that would have 4 robots and employment of workers to move component from robot to robot is eliminated.

Using this thinking, RTUs can serve a variety of tasks, aiding robots in part picking and selection, binning and transferring, palletizing, packing as well as machine loading and unloading . With the ability to bring a robot to do any number of these tasks rather than having a robot for each, production benefits.

When faced with heavy equipment and lots of moving parts, inclusion of a human workforce is time consuming and expensive. Each worker needs to be trained on the equipment, workspace, and the line. Safety risks are a larger concern when the handlers of heavy equipments and parts are human. Risk for injury increases with every additional worker. A reduction in required present work force doing dangerous and tiresome work will reduce injuries and lower insurance premiums. The addition of the RTU removes all these factors from the production plan as they have the ability to accomplish any and all tasks assigned to it. With no risk of human error or injury.

Simply put RTUs diversify and expand the work of robots in any multi-step production process. Integrated within the layout of the production sequence RTUs increase the flexibility and efficiency, which often turn into cost reductions.

Benefits of RTUs in Material Handling Applications:

- Capacity and Productivity

- Reduced man hours and the ability to operate persistently without interruptions

- Faster movement with less risk across long spans

- Unattended operation and reliability

- Reduced changeover time as multiple operating cycles can be programmed in

and swapped over at any time - Additional tasks - robots not operating as MHUs can be programmed to do

other ‘odd jobs’ such as deburring, parts inspection etc.

Labor:

- Using RTUs for material handling reduces recruiting, hiring and training costs, particularly where skill certificates such as forklift training are required

- Job satisfaction - workers have the opportunity to move up from simply

shuttling pallets and parts to more valuable jobs - Robots and RTUs are easily re-purposed as factory demands change so they

have a long payback life over many factory revisions

Quality:

- Automation is proven to improve consistency and quality

- There are fewer incidents and accidents which can damage parts or finished

goods during movement

Safety:

- Tending automated machinery that is fast moving is inherently dangerous

- Exposing fewer workers to hazardous areas even if they are only there for short

periods of time handling materials dramatically reduces the odds of a severe

accident

You can read about a recent custom Material Handling Unit developed by Lazerarc here (link to case study article).